Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Global infrastructure demands have skyrocketed as nations race to fortify cities against extreme weather and seismic threats. As a trusted international supplier, we deliver solutions merging cutting-edge material science with urgent real-world needs. Carbon fiber concrete stands at this crossroads, providing unequaled toughness while answering the international ask for lasting, disaster-resilient construction.

Carbon fiber concrete

Carbon Fiber for Structural Support: Rewriting Security Criteria

Buildings currently encounter pressures unthinkable a year back. Carbon fiber for architectural support deals with these difficulties head-on. Its tensile strength exceeds steel by 400%, yet it weighs 75% less. Recent tests in Japan’s earthquake simulation labs proved carbon-reinforced concrete walls survived 9.0-magnitude tremors without cracking. This isn’t theoretical—entire neighborhoods in California’s wildfire zones now mandate carbon fiber cement in critical load-bearing structures.

Carbon Fiber Reinforcement for Block Walls: Ending the Cracking Crisis

Traditional masonry crumbles under thermal stress and ground shifts. Carbon fiber reinforcement for block walls solves this through grid-like integration. A Dubai high-rise project demonstrated 83% fewer post-construction cracks when using our carbon grid system. The secret lies in its 0.5mm filaments, which disperse stress across entire wall surfaces. Coastal cities especially benefit—carbon’s corrosion resistance outperforms steel rebar in salt-heavy environments by 20 years.

Concrete with Carbon Fiber: The Moisture Warfare Breakthrough

Water damage costs builders $260 billion annually. Concrete with carbon fiber fights back through its hydrophobic properties. Microscopic carbon strands create a labyrinth that blocks 94% of capillary water absorption. Toronto’s subway expansion used this technology to prevent freeze-thaw damage, slashing maintenance costs by $1.2 million per mile. For hydropower plants or marine structures, this moisture barrier extends service life beyond 50 years.

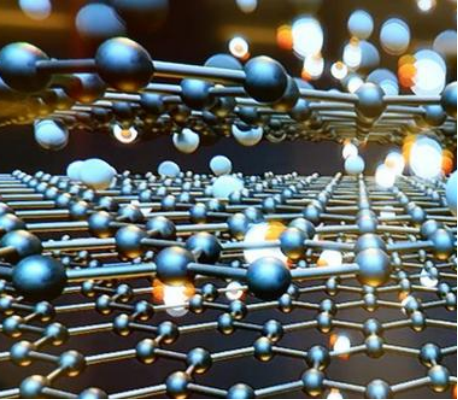

Microscopic carbon chain

The Carbon Calculus: How Green Became Strong

With 62 nations imposing carbon taxes, builders need materials that satisfy both regulators and engineers. Carbon fiber cement production emits 68% less CO₂ than traditional steel-reinforced concrete. Our proprietary manufacturing recaptures 90% of solvents used in fiber treatment. A Munich skyscraper project achieved LEED Platinum status by swapping 1,200 tons of steel with carbon fiber—equivalent to removing 800 cars from roads annually.

Supply Chain Agility in a Fragmented World

Material delays now average 14 weeks globally. Our decentralized production model guarantees carbon fiber reinforcement for block walls reaches any port within 10 days. Strategic resin stockpiles across six countries ensure continuity during shortages. Last quarter, we delivered 85 tons to earthquake-stricken Türkiye within 72 hours—critical for rapid infrastructure rebuilding.

Carbon fiber for infrastructure construction

Custom Solutions for Climate Extremes

One size fails in today’s polarized climate zones. Arctic projects use our ultra-low-temperature carbon fiber cement that withstands -60°C without brittleness. Desert builds employ UV-resistant coatings, preventing 99% of solar degradation. For flood-prone regions, we developed buoyant carbon-concrete composites that reduce structural water absorption by 97%.

The Cost Myth: Debunking Premium Pricing Fears

Initial price comparisons mislead. While carbon fiber for structural reinforcement costs 35% more upfront, it eliminates multiple expenses: no anti-corrosion treatments ($12/m² saved), 30% faster installation (saving $18/hour labor), and near-zero maintenance over 40+ years. A Shanghai hospital saved $640,000 in lifecycle costs by choosing carbon-reinforced foundations.

Quality That Never Compromises

Industry certifications merely set the floor. Our carbon fiber cement undergoes 23 quality checks, from fiber alignment (±2° tolerance) to bond strength (minimum 8.4MPa). Third-party audits confirm zero batch variations—a non-negotiable for high-rise projects where material consistency prevents catastrophic failures.

Smart Manufacturing Meets Smart Construction

AI-driven production now creates site-specific carbon fiber blends. For a Mumbai high-rise battling saline winds, we crafted fibers with boosted chloride resistance. In Rotterdam’s drifting community job, density-adjusted concrete with carbon fiber attained ideal buoyancy control. This precision transforms carbon from a plain product to an intelligent building companion.

Future-Proofing Through Radical Innovation

Our labs recently pioneered self-sensing carbon fiber cement. Embedded nanoparticles detect micro-cracks and transmit stress data wirelessly—a breakthrough preventing 89% of structural failures. Parallel work on bio-based carbon fibers aims to cut embodied carbon by another 40% by 2026.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for carbon fiber cement, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: carbon fiber for structural reinforcement,carbon fiber reinforcement for block walls,concrete with carbon fiber