Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

A release agent is a chemical substance used to form a film between the mold and the material being molded to prevent the material being molded from adhering to the surface of the mold, thereby facilitating mold release. Mold release agents have a wide range of applications in various manufacturing processes, especially in the production of plastics, rubber, metal casting, composites and concrete products.

The difference between these two types of mold release agents is shown in the following aspects, respectively:

I. Composition and form

An oily mold release agent is mainly composed of oil-based components such as waste engine oil, diesel oil or synthetic oil. The form is usually liquid, oily and non-volatile.

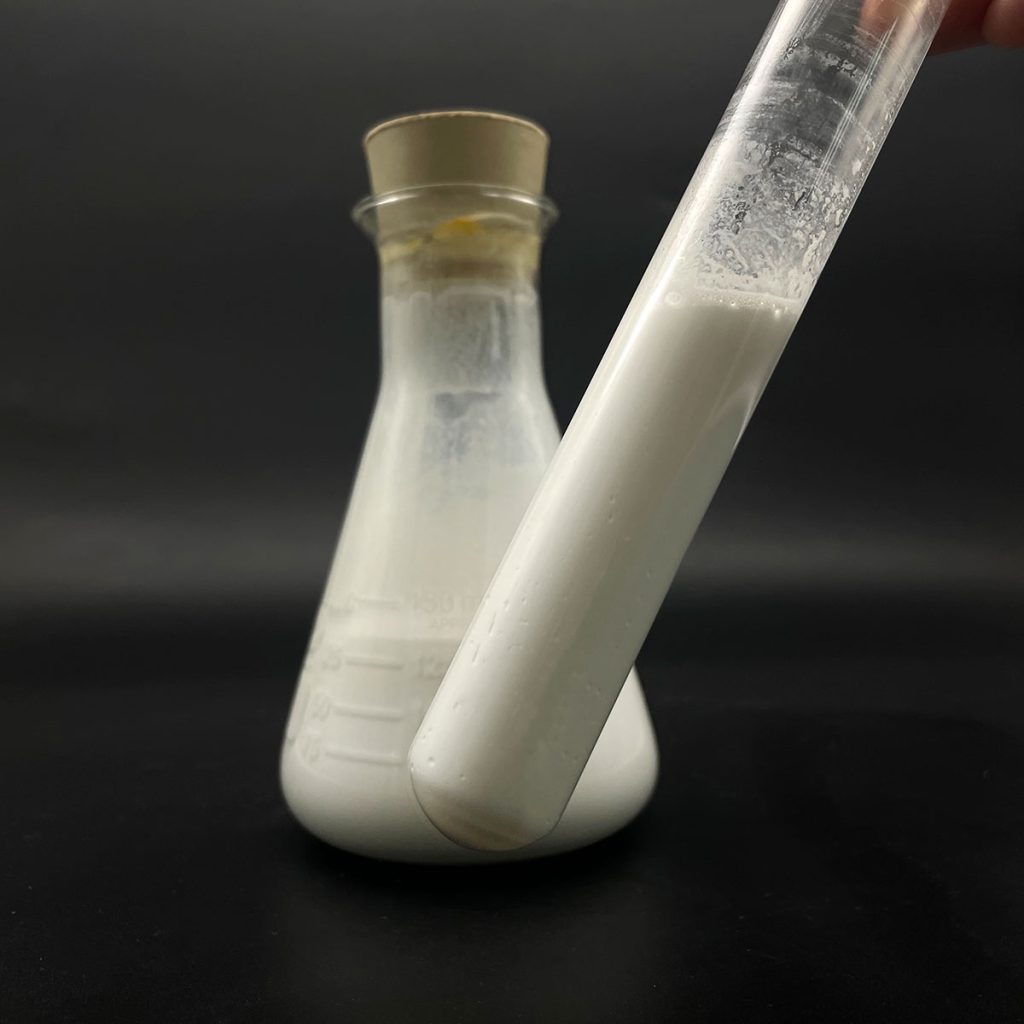

Aqueous release agents are mainly composed of water and emulsifiers, silicone oils, waxes, etc. The oily components are dispersed in water by emulsification technology. The form is also liquid, milky or transparent, but volatile.

Second, performance

Oily-release agents usually have a better release effect, especially for complex shapes and high-precision molds. Because its oily component provides better lubricity, it helps to reduce the friction on the mold surface. They are suitable for high-temperature environments and are not easy to decompose. The film it forms on the mold surface is thicker, and the release effect is long-lasting, but it may require more frequent cleaning of the mold, and the product surface will also have oil marks doped on the surface, which makes the surface unattractive.

Water-based release agents have a good release effect but may not be as good as oil-based release agents and are suitable for simple shapes and medium-precision molds. Lubricity is relatively weak but adequate for most applications. High-temperature resistance is fair and suitable for low to medium temperatures. The film formed is thin, and the release effect is relatively short but easy to clean.

Application

Oil-based mold-releasing agents have a wide range of applications, mainly used in metal casting, plastic injection molding, rubber molding, composite material molding and other fields, especially suitable for high temperature and high precision requirements of the occasion. Typical applications are automotive parts, aerospace parts, electronic components and so on.

Water-based mold-releasing agents are suitable for plastic injection molding, rubber molding, composite material molding and other fields, especially suitable for occasions with high requirements for environmental protection. Typical applications in building decoration materials, household goods, toys, etc..

Fourth, environmental protection

The oily components of the oil-based mold release agent may lead to environmental pollution and require strict waste liquid treatment after use. At the same time, there may be a strong oil odor, which has a certain impact on the operating environment.

Water-based release agent components are environmentally friendly, easy to biodegradation, and in line with environmental requirements. Almost no odor, less impact on the operating environment.

V. Use and maintenance

Oil-based release agents are usually used directly, sprayed or brushed on the mold surface. The surface of the mold is easy to accumulate oil film, which needs to be cleaned regularly to prevent the accumulation of dirt from affecting the release effect.

Water-based release agents are usually diluted with water in a certain proportion and sprayed or brushed on the mold surface. The film formed on the surface of the mold is thin, easy to clean and relatively simple to maintain.

Suggestions for selection

1. In terms of application requirements, if you need a better release effect and lubrication, especially in high temperatures and high precision requirements, choose an oil-based release agent. If you have higher requirements for environmental protection or the application is sensitive to smell, choose a water-based release agent. 2.

2. Before actual application, it is recommended to conduct a small-scale performance test to ensure that the selected release agent can meet the specific requirements.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for water-based mold release agents, please feel free to contact us and send an inquiry. (sales1@cabr-concrete.com)