Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

1. Chemical Framework of Protein-Based Foaming Agents

Protein-based Foaming Agents, originating from either animal or plant sources, are essential in producing lightweight, durable lathered concrete. Their chemical framework dictates their performance in terms of thermal conductivity, compressive toughness, and foam stability.

1.1 What Are animal Protein-Based Foaming Agents?

Animal protein-based foaming agents are generally sourced from collagen-rich products such as jelly, casein, or keratin. These proteins are composed of amino acid chains with hydrophobic and hydrophilic areas, allowing them to lower surface area tension and stabilize air bubbles in concrete blends. As an example, gelatin, a result of animal hides and bones, contains 18 necessary amino acids, consisting of glycine and proline, which add to its special frothing properties. Its molecular weight (2000– 6000 Da) and high solubility make it ideal for producing fine, consistent bubbles in concrete.

1.2 What Are Plant Protein-Based Foaming Agents?

Plant protein-based foaming agents, such as those derived from soy, pea, or wheat healthy proteins, depend on polypeptide chains rich in hydrophilic amino acids like lysine and arginine. These healthy proteins develop secure micelles in water, decreasing interfacial stress and enhancing foamability. For instance, soy healthy protein isolates, with a molecular weight of 10,000– 50,000 Da, exhibit outstanding foaming capability as a result of their versatile molecular framework and all-natural surfactant properties. Unlike animal healthy proteins, plant-based agents usually need alkaline pH conditions to denature and unfold their polypeptide chains for ideal performance.

2. Core Qualities of Animal and Plant Protein-Based Foaming Agents

The physical and chemical properties of these agents directly affect the thermal and mechanical behavior of foamed concrete.

2.1 Physical and Chemical Residences of animal Protein-Based Foaming Agents

Animal-derived foaming agents master foam security and temperature level resistance. Their high denaturation temperature level (60– 90 ° C )guarantees that bubbles remain intact during concrete treating, even under moderate warm conditions. For instance, gelatin-based agents can decrease thermal conductivity by 20- 30% compared to traditional concrete, making them optimal for shielding applications. Additionally, their alkaline solubility (pH 7– 10) allows compatibility with cementitious systems, while their low viscosity (10– 50 cP) promotes easy mixing.

Nevertheless, animal healthy proteins deal with obstacles in long-term toughness. Long-term exposure to wetness or acidic atmospheres can result in hydrolysis, degrading the foam framework and increasing thermal conductivity over time.

2.2 Physical and Chemical Residences of Plant Protein-Based Foaming agents

Plant-based agents use eco-friendly advantages, however, require a careful formula. Their lower denaturation temperature (40– 60 ° C )makes them appropriate for cold-weather applications, though they may shed security at higher heating temperatures. For example, soy protein isolates lower thermal conductivity by 15– 25% but require pH modification (8– 10) to preserve foam integrity.

A crucial benefit of plant healthy proteins is their renewable source and biodegradability, aligning with eco-friendly building requirements. However, their higher thickness (50– 200 cP) can make complex mixing, and their susceptibility to microbial destruction may restrict their usage in moist environments.

| Parameter | Specification |

| Product Name | High-Concentration Foam Concrete Protein Foaming Agent |

| Appearance | Brownish-brown viscous liquid |

| Density | 1.04 g/cm³ |

| pH Value | 6.8–7.2 |

| Solid Content | 38–42% |

| Water Absorption | ≥40% |

| Color (APHA) | ≤50 (measured by Hazen units) |

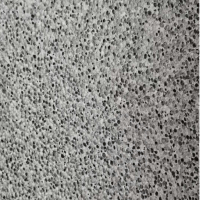

| Foam Stability | High-strength, long-lasting bubbles (no collapse or shrinkage) |

| Bubble Diameter Uniformity | Uniform closed-cell structure with consistent pore size |

| Corrosion Resistance | Non-corrosive to equipment and environment |

| Environmental Impact | Non-toxic, non-polluting |

| Consumption Rate | 0.4–0.8 kg/m³ (for concrete foam production) |

| Freezing Point | -10°C |

| Safety | Chemically inert, non-flammable, odorless, non-irritating to skin |

| Packaging | 200 kg per drum; 80 drums (16 tons) in a 20GP container |

| Storage | Store in a cool, dry place (avoid direct sunlight) |

| Application | Foamed concrete, insulation blocks, wall panels, and industrial lightweight structures |

| Key Features | – Rich foam generation <br> – High bubble strength <br> – Excellent thermal insulation <br> – Eco-friendly and sustainable |

3. Benefits and Limitations of Protein-Based Foaming agents

Both animal and plant-derived agents have distinct toughness and weak points in foamed concrete production.

3.1 Advantages and Limitations of Animal Protein-Based Foaming Agents

3.1.1Advantages

Superior Foam Security: Develops great, consistent bubbles that boost compressive stamina by 10– 15%.

Heat Resistance: Maintains foam framework during treating, also in warm climates.

Compatibility with Cement: Alkaline solubility ensures seamless integration into concrete matrices.

3.1.2Limitations

Ecological Concerns: Stemmed from animal results, elevating ethical and sustainability concerns.

Hydrolysis Susceptibility: Long-term direct exposure to dampness damages the foam framework.

Price: Greater manufacturing expenses as a result of sourcing and processing constraints.

For instance, a research study in Germany discovered that gelatin-based foamed concrete kept 90% of its original strength after thirty days, outperforming plant-based options in dry environments.

3.2 Benefits and Limitations of Plant Protein-Based Foaming agents

3.2.1Benefits

Sustainable Sourcing: Utilizes farming waste (e.g., soy hulls) to decrease carbon impact.

Reduced pH Sensitivity: Carries out well in mildly acidic environments, widening the application extent.

Cost-Effectiveness: Lower basic material prices compared to animal healthy proteins.

3.2.2Limitations

Thermal Instability: Foam breaks down at temperatures over 60 ° C, restricting use in high-heat zones.

Viscosity Challenges: Requires specific blending equipment to manage higher viscosity.

Longevity Concerns: Susceptible to mold growth in moist problems.

In a study from China, soy-based foamed concrete revealed a 12% renovation in thermal insulation but called for added preservatives to avoid microbial deterioration.

4. Applications of Protein-Based Foaming agents

The choice between animal and plant proteins relies on project-specific requirements.

4.1 Applications of Animal Protein-Based Foaming agents

Industrial Insulation: Ideal for refractory cellular linings in steel mills because of high-temperature stability.

Architectural Facades: Utilized in lightweight attractive panels for aesthetic and thermal advantages.

ColdStorage Facilities: Improves insulation in fridge freezer walls, reducing power usage by 25- 30%.

As an example, a European producer makes use of gelatin-based agents in prefabricated concrete blocks, accomplishing 0.15 W/m · K thermal conductivity– a 40% enhancement over traditional techniques.

4.2 Applications of Plant Protein-Based Foaming Agents

Eco-friendly Structures: Follow LEED accreditation for eco-friendly building.

Agricultural Shelters: Gives cost-effective insulation for greenhouses in temperate climates.

Emergency Situation Shelters: Lightweight foamed concrete panels enable rapid deployment in disaster areas.

A notable example is making use of soy healthy protein agents in low-cost housing projects in India, where they minimized material costs by 35% while fulfilling IS 10262 requirements for compressive toughness.

5. Technical Advantages of Protein-Based Foaming Agents

Protein-based agents use innovative remedies for stabilizing efficiency, sustainability, and cost.

Customized Solution: Changing amino acid make-up enables customization for details thermal and mechanical demands.

Synergistic Blending: Incorporating animal and plant proteins can alleviate individual weaknesses– e.g., gelatinsoy mixes enhance both foam stability and ecofriendliness.

Smart Launch Modern technology: Encapsulated healthy proteins can launch stabilizers throughout curing, maximizing long-term efficiency.

An advancement in Japan entails enzymatically changed soy healthy proteins, which enhance foam life time by 50% and lower thermal conductivity to 0.12 W/m · K– a gamechanger for zero-energy buildings.

Conclusion: Revolutionize Concrete with Protein-Based Development

Protein-based foaming agents are a powerhouse of technology for the building and construction industry, providing exceptional control over thermal and architectural homes. While animal-based proteins provide durable performance in severe conditions, plant-based options give lasting, cost-effective solutions for contemporary projects.

For home builders looking to decrease energy intake, improve longevity, or fulfill green accreditations, protein-based agents are a must-have device. By leveraging the distinct strengths of animal and plant proteins, you can open new possibilities in a clever, resistant framework.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of protein-based foaming agents with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for protein-based foaming agents, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: concrete foaming agent,plant protein based foaming agents,animal protein-based foaming agents