Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

In the ever-evolving building and products market, advancement is vital to remaining ahead. Amongst the cutting-edge technologies reshaping modern building and construction, the Lightweight Concrete Foam Generator stands apart as a transformative tool. This tool, commonly referred to as a CLC (Mobile Lightweight Concrete) frothing maker, has changed the manufacturing of aerated concrete by enabling specific, efficient, and scalable foam generation. Whether you’re a skilled engineer, a job supervisor, or a business owner exploring new opportunities, comprehending the Lightweight Concrete Foam Generator and its efficiency criteria is essential to unlocking its full capacity. This short article will certainly explore the basics of this equipment, highlight its five most essential efficiency metrics, evaluate its pros and cons, and discover its diverse applications throughout markets.

1. What Is a Lightweight Concrete Foam Generator?

A Lightweight Concrete Foam Generator is a customized device created to develop stable, high-quality foam for use in lightweight concrete manufacturing. At its core, the generator mixes air with a lathering agent (usually a surfactant-based option) to create great, consistent bubbles. These bubbles are then integrated right into a cementitious slurry to create aerated concrete, a material prized for its reduced density, outstanding thermal insulation, and architectural versatility.

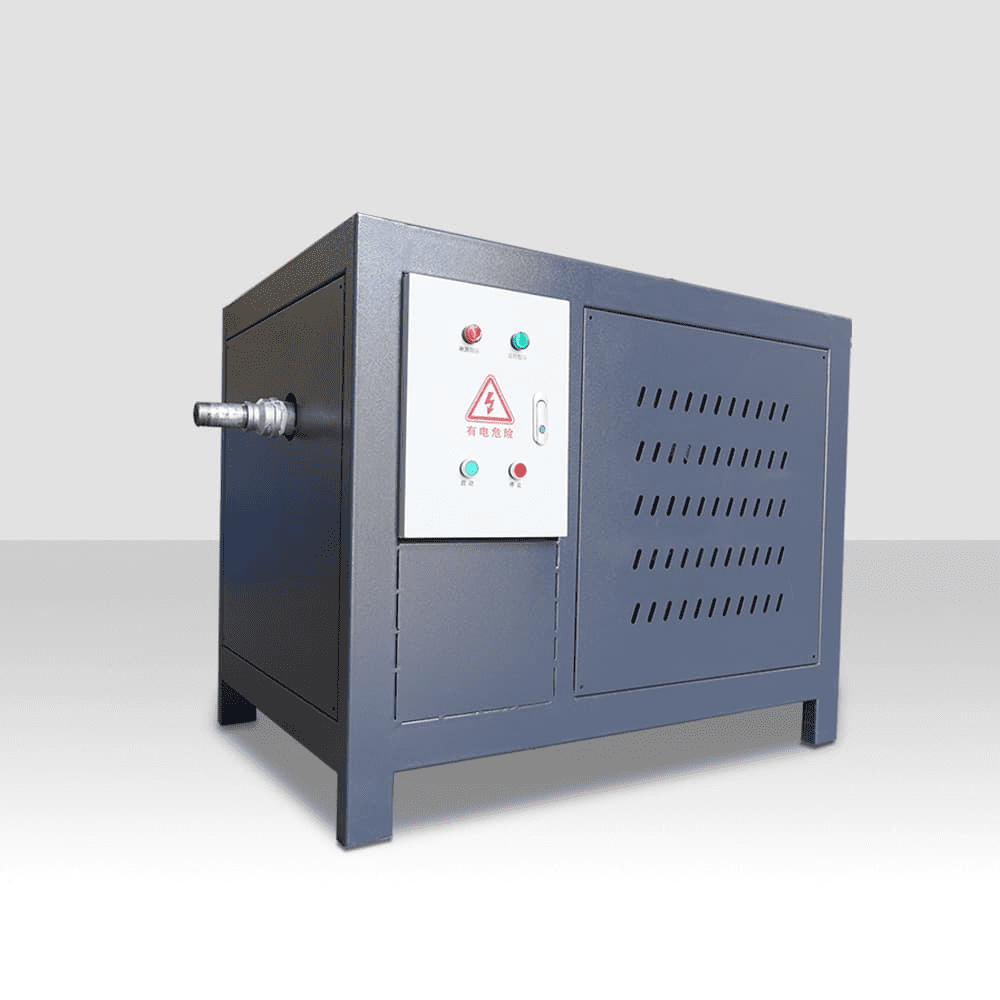

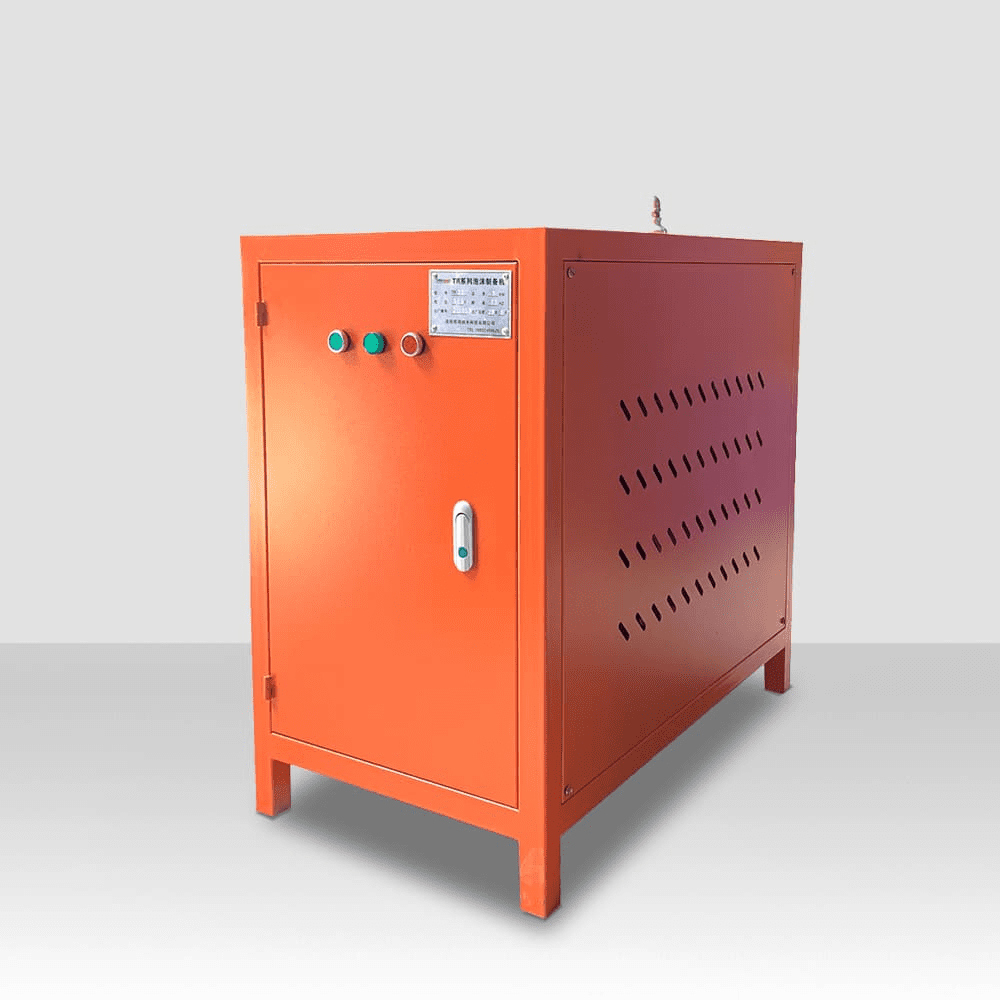

The generator’s layout incorporates innovative engineering principles to ensure optimal foam stability, also under differing ecological conditions. Modern devices are outfitted with automated systems, precision controls, and resilient parts to deal with the demands of large-scale projects. As an example, the TR75 Concrete Foam Generator (a preferred design in the sector) flaunts an optimum foam result of 20 m FIVE/ h and a power ranking of 7.5 kW, making it ideal for high-volume applications.

The relevance of this equipment depends on its ability to simplify the manufacturing of lightweight concrete, which is increasingly sought after for energy-efficient buildings, infrastructure jobs, and eco-friendly building techniques. By lowering product weight and improving insulation in residential or commercial properties, the generator contributes to setting you back financial savings, sustainability, and compliance with modern-day building codes.

| Model | TR75 |

| Maximum foam output(m3/h): | 7.5 |

| Motor voltage(V) : | 380 |

| Work rate(KW): | 7.5 |

| Foaming speed(L/m): | 300 |

| Bubble bleeding(kg/m3): | 70 |

| Dimensions(mm): | 1200*700*1000 |

| Weight(kg): | 300 |

2. Lightweight Concrete Foam Generator: 5 Performance Parameters You Must Know Prior To Usage

Prior to buying a Lightweight Concrete Foam Generator, it’s critical to examine its performance metrics. These specifications identify the maker’s efficiency, reliability, and viability for particular tasks. Below are the 5 most critical elements to think about:

2.1 Foam Outcome Ability

The maximum foam result (measured in cubic meters per hour) is a specifying feature of any kind of generator. For example, the TR75 model can create up to 20 m FIVE/ h of foam, while smaller-sized units like the TR11 provide a more portable remedy with an output of 10 m FIVE/ h. High-capacity generators are optimal for large-scale tasks such as roadway building and construction or industrial flooring, whereas portable versions suit smaller applications like household insulation.

2.2 Power Consumption and Electric Motor Specifications

The generator’s power ranking (in kilowatts) directly impacts its functional expenses and energy effectiveness. Most industrial-grade makers operate on 380V three-phase power, with motor scores varying from 3 kW to 15 kW. A higher power result ensures much faster foam manufacturing, however might raise electrical energy prices. For example, the HWF100 Automatic Lightweight Concrete Station takes in 54 kW overall, reflecting its high-performance capacities.

2.3 Foam Stability and Harmony

The top quality of the foam– its harmony, stability, and resistance to collapse– is critical for producing consistent lightweight concrete. Advanced generators make use of precision nozzles and high-pressure systems to create fine, evenly dispersed bubbles. The TR75 achieves a foam density of 2040 g/L, ensuring minimal air loss throughout mixing and pouring. Poor foam security can cause irregular concrete sets, compromising architectural integrity.

2.4 Alleviate of Procedure and Automation

Modern generators emphasize user friendliness and automation. Functions like PLC control systems, touchscreens, and remote monitoring streamline procedures and decrease the threat of human mistakes. The HWF100 design, for example, incorporates PLC-based automation for seamless mixing, pumping, and quality assurance. Such functions are especially useful for big teams or jobs calling for 24/7 manufacturing.

2.5 Maintenance Demands and Resilience

Longevity and maintenance-free operation are vital for long-term price efficiency. Generators with corrosion-resistant elements (e.g., stainless steel nozzles) and modular designs (for easy component replacement) minimize downtime. The TR75 uses precision-engineered parts to reduce damage, while the HWF100 includes self-cleaning mechanisms to prevent obstructing. Routine upkeep schedules and accessibility to extra components are likewise essential considerations.

3. Lightweight Concrete Foam Generator: Advantages And Disadvantages

While the Lightweight Concrete Foam Generator supplies numerous advantages, it is very important to weigh these against possible downsides to make an informed decision.

3.1 Benefits

Boosted Material Qualities: The foam created by these generators boosts concrete’s thermal insulation, fire resistance, and soundproofing capabilities. For instance, aerated concrete made with TR75 foam attains a thermal conductivity of 0.08– 0.25 W/m · K, making it optimal for energy-efficient buildings.

Price Efficiency: By reducing material weight and transportation costs, lightweight concrete reduces project expenses. The HWF100 system, for example, can pump 70- 100 m SIX/ h of concrete, significantly accelerating building timelines.

Ecological Advantages: Lightweight concrete decreases carbon impacts by using commercial results (e.g., fly ash) and decreasing concrete usage. This lines up with international sustainability goals and green structure accreditations.

Flexibility: From roofing insulation to passage linings, these generators support a wide range of applications. Their adaptability ensures they stay appropriate across varied industries.

3.2 Downsides

High First Investment: Premium designs like the TR75 or HWF100 require considerable upfront expenses. Nevertheless, their long-term savings often validate the expenditure.

Technical Knowledge Required: Operators require training to manage complex systems, particularly those with automation features. This may increase labor costs at first.

Foam Quality Level of sensitivity: The efficiency of the generator is heavily depending on the high quality of the foaming agent and water purity. Contaminations can result in unpredictable foam, demanding stringent quality control measures.

4. Applications of the Lightweight Concrete Foam Generator

The Lightweight Concrete Foam Generator is a foundation of contemporary construction, with applications spanning several fields:

4.1 Structure and Building

Insulation Layers: Lightweight concrete is used in roof covering, walls, and floors to enhance energy efficiency. As an example, lathered concrete with a thickness of 450 kg/m five provides remarkable insulation without jeopardizing architectural stamina.

Structural Fillers: In structure gaps and beam of light cavities, it lowers dead loads and prevents breaking.

4.2 Framework Projects

Roadway and Railway Embankments: Foam concrete supports soft soils and lowers settlement dangers. Its low thickness (300– 1600 kg/m FIVE) makes it suitable for bridge joints and cut-and-fill procedures.

Water Drainage Systems: Permeable foam concrete layers enhance stormwater management in freeways and metropolitan areas.

4.3 Environmental Design

Landfills and Waste Management: Foam concrete works as a capping layer to stop leachate contamination.

Disintegration Control: Its lightweight and porous structure is use in coastal security and incline stabilizing tasks.

4.4 Industrial and Specialized Uses

Fireproofing Panels: With a fire resistance rating of over 3 hours, foam concrete is used in commercial centers and high-rise buildings.

Soundproofing Barriers: In freeways and trains, it reduces environmental pollution.

5.Conclusion: A GameChanger for Modern Construction

The Lightweight Concrete Foam Generator is not simply a device– it’s a stimulant for advancement in the building and construction market. Its capacity to produce high-quality, stable foam at a range makes certain the creation of products that are lighter, stronger, and more sustainable. By understanding its five vital efficiency specifications and understanding its advantages and disadvantages, specialists can harness this modern technology to transform tasks, lower costs, and fulfill international sustainability criteria.

For organizations looking to remain affordable, investing in a Lightweight Concrete Foam Generator is a calculated action. Whether you’re developing the next-generation high-rise or renewing a country framework, these tools offer an advanced option to age-old difficulties. Accept the future of construction– effortlessly, efficiently, and fairly– with the power of foam generation.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Lightweight Concrete Foam Generator with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Lightweight Concrete Foam Generator, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: foam generator for lightweight concrete,clc foam generator