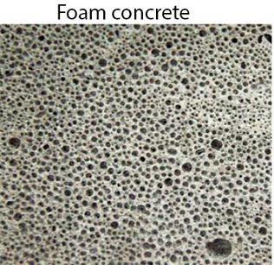

Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Compared to aerated concrete block walls, lightweight foam partition walls offer lower overall construction costs. Currently, the unit price of lightweight partition walls (excluding plastering) is approximately 23% lower than that of aerated concrete block walls (including plastering), significantly reducing total construction costs.

Foam lightweight concrete partition wall panels align more closely with green building principles. Over 85% of the raw materials are recyclable construction waste, and the manufacturing process is highly automated. On-site assembly is standardized and streamlined.

Foam lightweight concrete partition wall panels offer rapid construction speeds and labor savings. The installation process for lightweight partition wall panels is clear and efficient, with two workers averaging 25–30 square meters per day.

Additionally, they can be directly coated with putty without plastering, significantly improving construction efficiency.

Foam lightweight concrete partition wall panels do not require plastering and can be directly coated with putty, offering significant advantages for developers in terms of cost control and construction site management. Foam lightweight concrete partition wall panels also have a natural advantage: direct application of putty ensures vertical and horizontal alignment meets standards. Fewer auxiliary materials are required for installation. Lightweight partition wall panels only need a small amount of U-shaped brackets and crack-resistant mortar, thereby reducing auxiliary material costs.

Foam lightweight concrete partition wall panels have excellent fire-resistant properties and are environmentally friendly. Their non-combustibility meets Class A standards, with a fire resistance time exceeding 4 hours at 1000°C. The materials used in foam lightweight concrete partition wall panels are all environmentally friendly products and do not contain substances harmful to the human body. They can expand indoor clear space. Foam lightweight concrete partition wall panels can fully expand the building space. When using traditional construction methods, interior partition walls are typically constructed using aerated concrete blocks with a design thickness of 200 millimeters, resulting in a total wall thickness of 250 millimeters, including plaster layers on both sides. However, when designing lightweight partition wall panels, no plastering is required, and the finished wall thickness is only 100 millimeters.

Installing indoor electrical wiring can save labor costs, as no grooving is required. Simply position the base box, drill holes at designated locations, and run the pipes through the pre-drilled holes in the partition wall, thereby saving on grooving and subsequent maintenance costs. The sound insulation performance meets the sound insulation requirements for residential buildings, with a decibel level below 45 (dB).

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Calcium formate over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Hand-synthesised Cellular Concrete Foam, please feel free and contact us: sales1@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.