Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Review of Concrete Admixture

Concrete admixtures are ingredients consisted of in the concrete mix prior to or during mixing to modify particular properties of the concrete, either in its newly mixed or hard state. These ingredients can improve workability, strength, setting time, and sturdiness of concrete, making them vital in modern building and construction methods.

Attributes of Concrete Admixture

Workability Enhancers: Boost the flow and handling of the concrete mix, lowering the initiative needed for putting and finishing.

Accelerators: Speed up the setup and reinforcing process of concrete, allowing quicker type removal and faster job progress.

Retarders: Slow down the hydration procedure, offering more time to deliver and put the concrete, particularly useful in hot weather or big pours.

Water Reducers (Plasticizers): Reduce the quantity of water called for to attain a provided downturn, causing higher stamina and much better longevity.

Superplasticizers: An extra potent variation of water reducers, permitting considerable water decrease without loss of workability.

Air-Entraining Agents: Introduce little air bubbles right into the concrete to improve freeze-thaw resistance and improve workability.

Rust Preventions: Safeguard embedded metals such as support bars from corrosion, extending the lifespan of the concrete framework.

Coloring Representatives: Made use of to transform the color of the concrete, preferred in architectural applications.

Waterproofing Admixtures: Boost the impermeability of concrete, making it more immune to water infiltration and leakage.

Fiber Reinforcements: Include fibers right into the mix to raise tensile sturdiness and lessen splitting.

Applications of Concrete Admixture

Admixtures are widely utilized throughout different building and construction markets:

Residential Structure: To guarantee durability and lengthy life of home structures, wall surface areas, and floorings.

Commercial and Business Projects: For high-performance concrete in frameworks, bridges, and freeways.

Framework Development: In the construction of dams, passages, and various other large-scale projects needing particular concrete buildings.

Historic Repair: To match the original buildings of historic concrete and masonry while improving longevity.

Environmental Projects: In green building techniques, where sustainability and marginal ecological impact are priorities.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality concrete admixture. We have a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Concrete Admixture, please feel free and contact us: sales@cabr-concrete.com

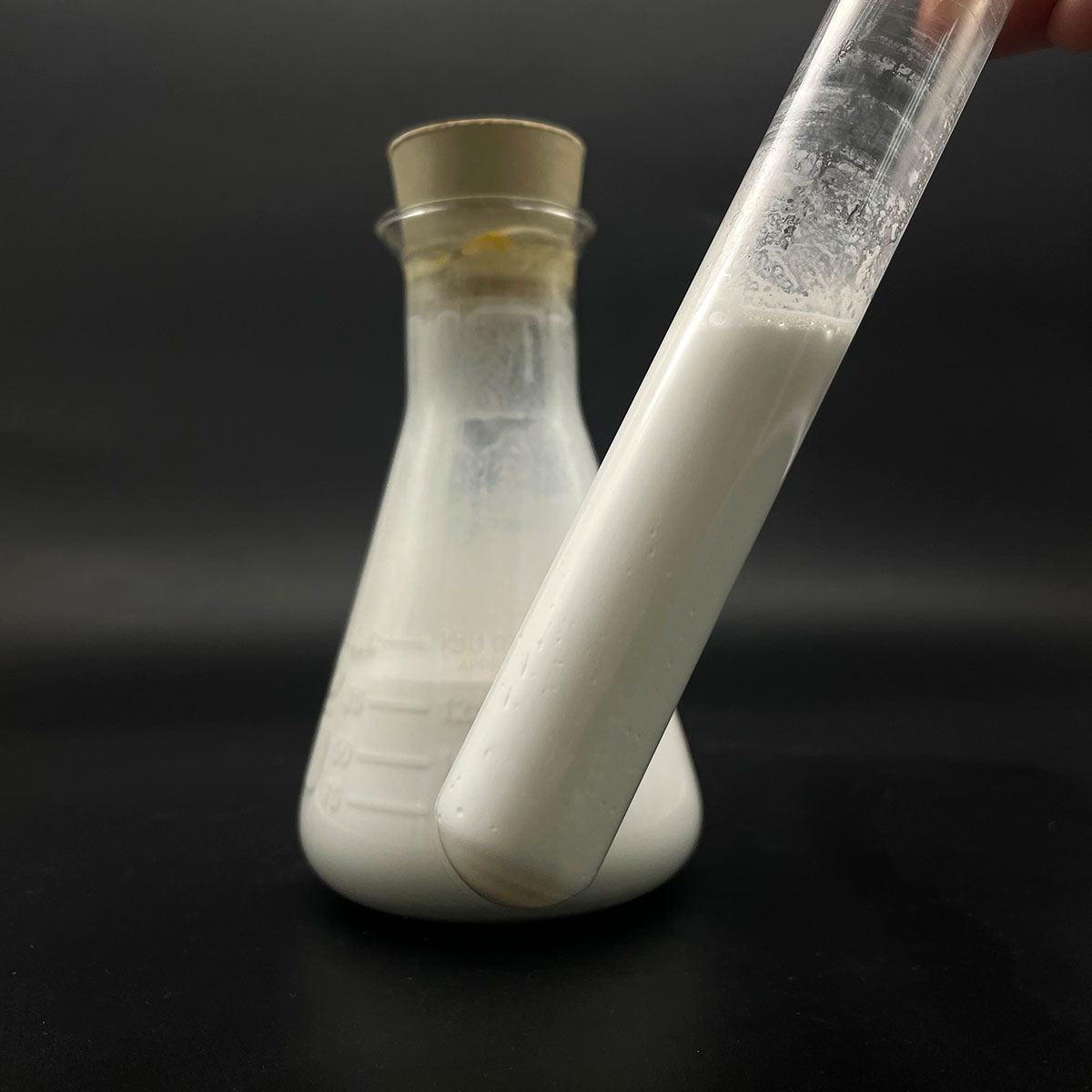

Package of Concrete Admixture

25Kg, 200kg, stored at room temperature away from light, moisture and rain.

Storage of Concrete Admixture

Paper plastic composite packaging lined with plastic bags

FAQs of Concrete Admixture

Q: How do fibers enhance concrete?

A: Fibers work as interior support, linking micro-cracks and enhancing the complete mechanical domestic or industrial homes of the concrete.

Q: Are concrete fibers pricey?

A: The expense varies depending on the type of fiber and amount required. Generally, while fibers could include in first costs, they can minimize long lasting expenditures through boosted strength and less repairings.

Q: Can concrete fibers change rebar?

A: While fibers boost a number of aspects of concrete performance, they usually do not fully change conventional rebar in essential load-bearing structures. Nevertheless, they can frequently lower the amount of rebar required.

Q: Exist any type of type of environmental worry about utilizing concrete fibers?

A: The environmental impact relies on the type of fiber used. Synthetic fibers are derived from petrochemicals, whereas all-natural fibers are naturally degradable however may have restricted efficiency. Sustainability elements to take into consideration must help the choice of fiber kind.

Q: Simply just how do I mix concrete fibers?

A: Fibers are typically included right to the concrete mixer at the specified dose price. Correct blending makes sure consistent blood circulation throughout the concrete. Producer guidelines should constantly be followed.