Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

1.What is fiber-enhanced concrete and its core residential properties?

1.1 Physical properties of fiber-reinforced concrete

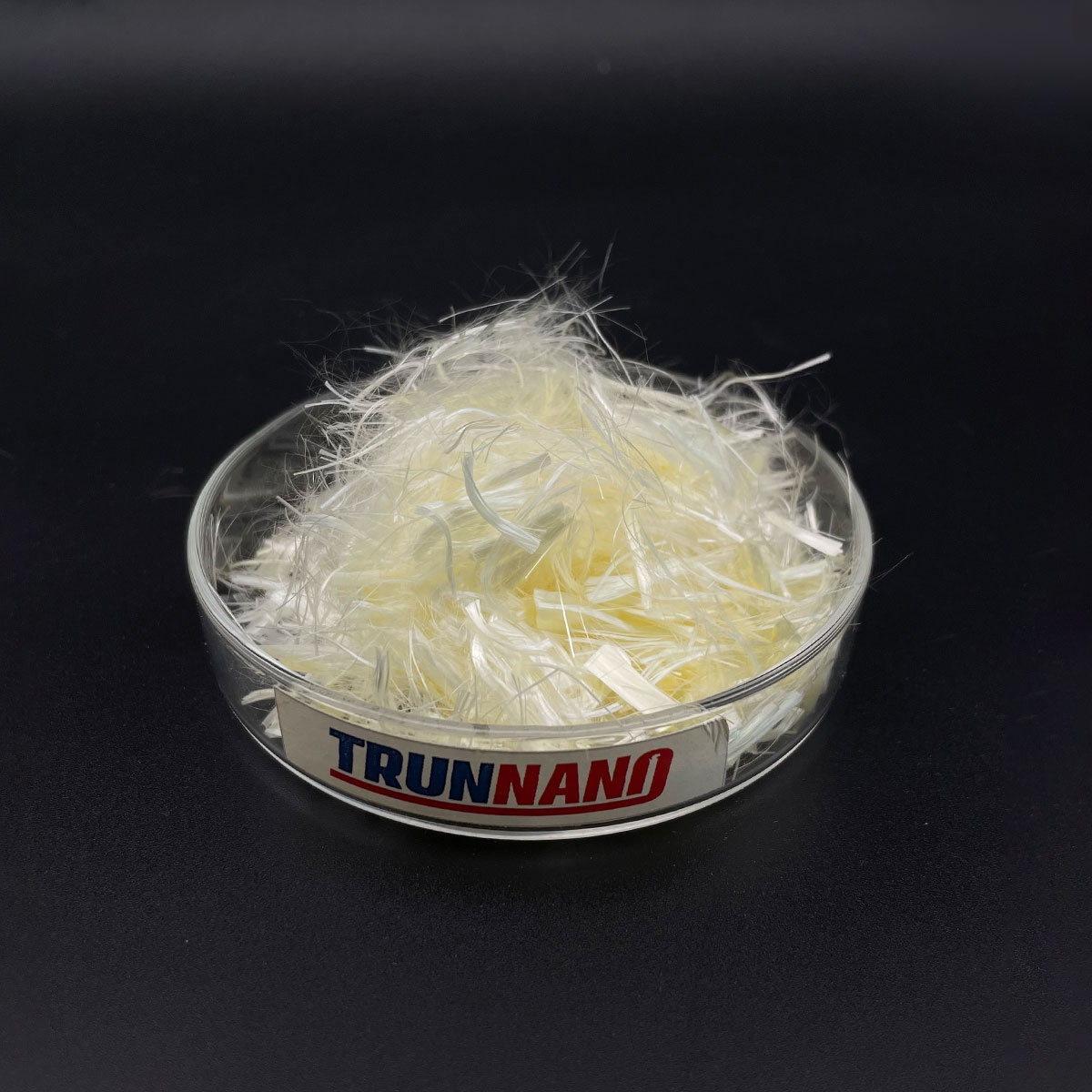

Fiber-enhanced concrete (FRC) is a modern building material that incorporates conventional concrete with ingrained fibers to enhance performance. These fibers are commonly constructed from polypropylene (PP fibers), polyvinyl alcohol (PVA), or steel and are mixed into the concrete matrix throughout the production process. These fibers work as support systems, boosting the product’s capability to withstand anxiety, fracturing, and deformation. Literally speaking, FRC has greater tensile strength compared to typical concrete, permitting it to resist bending and cracking under load. It likewise shows enhanced adaptability, consequently reducing the risk of fragile failure. Chemically speaking, FRC is immune to alkali aggregate reactions and deterioration, making it ideal for severe settings. As an example, the enhancement of polypropylene fibers improves influence resistance, while PVA fibers assist in boosting ductility and control splits. This performance mix makes FRC a global remedy for applications that require durability and flexibility.

2.Benefits and drawbacks of fiber-strengthened concrete

2.1 Advantages of Fiber Reinforced Concrete

Contrasted to conventional concrete, the presence of fibers such as polypropylene or PVA allows it to manage microcracks throughout the treating process. This reduces the need for extra reinforcement, saving time and labor costs. FRC also boosts the durability of the product, enabling it to take in the energy of effect or resonance without failure. For instance, PVA fibers are especially efficient in applications that require high tensile toughness, such as industrial flooring.

2.2 Disadvantages of Fiber Reinforced Concrete

Nonetheless, FRC is not without its drawbacks. Compared to basic concrete, adding fibers enhances product prices, which may limit its fostering in budget delicate tasks. On top of that, improper blending or fiber distribution can bring about weak points and damage to architectural honesty. Although PP fibers are cost-effective, they might weaken under long-term direct exposure to ultraviolet radiation, limiting their use in outside settings.

Data of PVA Fiber:

| Items | Unit | Quality |

| Titer | dtex | 2.0±0.25 |

| Dry Tenacity | CN/dtex | ≥14.0 |

| Initial Modulus | CN/dtex | ≥350 |

| Dry EXTat break | % | 6.5±1.0 |

| Loss in Hot Water | % | ≤2.0 |

| Size | 2.00 dtexX6mm |

3.How Fiber Reinforced Concrete Changes Modern Architecture

FRC has actually been extensively used in the fields of style and engineering because of its unique performance. In roadway and bridge building, polypropylene fibers are normally used to decrease plastic contraction splits and extend the service life of the roadway surface. For high flow industrial flooring, PVA fiber has outstanding wear resistance, lessening the maintenance required to the greatest extent possible.

Marine frameworks such as anchors and seawalls gain from the corrosion resistance of FRC, ensuring their lifespan in saltwater environments. The passage, cellular lining, and airport terminal runway additionally rely on FRC to hold up against heavy loads and dynamic stresses. In residential and business structures, FRC is use for pieces, walls, and columns to improve structural security. Innovations in the field of fiber optic technology are constantly expanding the applications of FRC, including 3D printed structures and seismic applications.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of PP Fiber and PVA Fiber with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for PP Fiber and PVA Fiber, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: polypropylene fiber,pp fibers,pva