Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

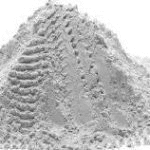

In the ever-evolving globe of building and construction and layout, products that blend performance with aesthetics are becoming progressively essential. Among these, White Cement stands apart as a revolutionary item that not just meets architectural needs but also boosts aesthetic allure. Whether you’re an engineer, a contractor, or a designer, understanding the complexities of White Cement can unlock brand-new possibilities for your projects. This article dives deep into the enigmas of White Cement, discovering its make-up, residential properties, benefits, drawbacks, and applications. By the end, you’ll obtain an all-natural perspective on why this product is improving modern-day building and construction and style.

1. What Is White cement?

White cement, also referred to as White Rose City cement, is a customized type of cement identified by its high brightness and low iron oxide (Fe ₂ O SIX) content. Unlike standard grey cement, which acquires its color from iron substances, White Cement is carefully crafted to minimize impurities that influence its color. This causes a product that is both visually striking and chemically robust.

1.1 The Ingredients Behind White cement

At its core, White Cement is crafted from naturally pure resources. The primary elements consist of limestone, clay, and silica, which are meticulously chosen to make certain marginal iron and manganese material. These materials are ground into a fine powder, combined, and then heated up in a kiln at temperatures going beyond 1450 ° C. The resulting cement clinker is further processed by adding plaster to regulate setting time and boost workability.

What collections White cement apart is the strict control over its chemical composition. As an example, the iron oxide content is typically below 0.5%, contrasted to 3– 6% in common cement. This precision makes sure an end product with a minimum brightness of 87%, making it excellent for applications where shade pureness is vital.

1.2 Physical Characteristics of White Cement

The physical features of White cement are customized to satisfy both structural and ornamental requirements. Key characteristics include:

High Whiteness: As pointed out, its purity guarantees a clean, intense appearance.

Fine Grinding: The cement is ground to a really great fragment size, improving its capacity to produce smooth, even surfaces.

Reduced Warmth of Hydration: This reduces the threat of thermal cracking in large frameworks.

Durability: Despite its visual emphasis, White Cement keeps the strength required for building, with compressive toughness ranging from 32.5 MPa to 52.5 MPa.

These residential properties make it a versatile selection for projects that demand both strength and appeal.

1.3 Chemical Residues of White cement

Chemically, White cement shares similarities with standard cement; however splits in critical means. The absence of iron oxide means it resists yellowing or discoloration gradually, even when subjected to sunlight. Additionally, its reduced sulfur trioxide (SO TWO) content (≤ 3.5%) prevents efflorescence– an unusual problem in grey cement where salts move to the surface.

The chemical security of White cement also enables it to bond effortlessly with pigments and ingredients, enabling the production of custom-colored cement and mortar. This opens the door to cutting-edge designs in architecture and interior spaces.

| Model | Whiteness | Strength Grade | Flexural strength(MPa) | Compressive strength(MPa) | ||||

| 1d | 7d | 28d | 1d | 7d | 28d | |||

| 90 | ≥90 | Ⅰ | 4.0 | 5.5 | 7.0 | 30.0 | 42.5 | 46.0 |

| Ⅱ | 7.0 | 8.0 | 8.5 | 55.0 | 72.5 | 76.0 | ||

| 80 | ≥80 | Ⅰ | 4.0 | 5.5 | 7.0 | 30.0 | 42.5 | 46.0 |

| Ⅱ | 7.0 | 8.0 | 8.5 | 55.0 | 72.5 | 76.0 | ||

| 75 | ≥75 | Ⅰ | 4.0 | 5.5 | 7.0 | 30.0 | 42.5 | 46.0 |

| Ⅱ | 7.0 | 8.0 | 8.5 | 55.0 | 72.5 | 76.0 | ||

2. The Benefits and Drawbacks of White cement

No product lacks its tradeoffs. While White Cement provides amazing advantages, it additionally includes certain constraints. Understanding these can help you make notified choices regarding its usage.

2.1 Benefits of White Cement

Aesthetic Quality: Its immaculate white shade is unequaled, making it the go-to choice for tasks where aesthetic charm is nonnegotiable. From luxury villas to high-end industrial rooms, White Cement transforms average structures into works of art.

Adaptability in Layout: Whether use in waterproof finishings, tinted cement, or complex sculptures, White Cement adapts to a variety of creative applications.

Sturdiness: In spite of its fragile appearance, White cement boasts impressive mechanical stamina, ensuring durability in both interior and outside atmospheres.

Reduced Upkeep: Its resistance to staining and fading minimizes the need for constant fixings or reapplications.

Sustainability: Modern production procedures focus on power performance, aligning with eco-friendly structure standards.

2.2 Disadvantages of White Cement

Greater Cost: Due to the rigid manufacturing demands, White cement is normally 30- 50% extra expensive than grey cement. This expense can be an obstacle for budget-sensitive projects.

Sensitivity to Impurities: Even minor contamination during blending or application can jeopardize its whiteness. This requires meticulous handling and storage.

Restricted Schedule: In some areas, sourcing White cement might call for prolonged preparations or specialized providers.

Complicated Color Matching: While White Cement can be tinted, achieving consistent pigmentation across big surfaces needs expertise and high-quality pigments.

Despite these difficulties, the one-of-a-kind advantages of White Cement usually outweigh its disadvantages, specifically in high-profile or design-driven jobs.

3. Applications of White cement

The flexibility of White Cement has actually led to its extensive adoption throughout numerous industries. Let’s discover some of its most impactful applications.

3.1 Building and Ornamental Uses

In design, White cement is a game-changer. It is regularly used in white cement facades, water-washed rock finishes, and brightened terrazzo floors. For example, the Burj Khalifa in Dubai employs White cement to preserve its smooth, modern aesthetic. Similarly, luxury resorts and hotels leverage their illumination to produce spa-like interiors and beautiful swimming pool areas.

3.2 Artistic and Sculptural Creations

Artists and artists prefer White Cement for its capability to capture fine details and vivid shades. It is ideal for sculptures, murals, and decorative wall surface panels, offering a canvas for imagination. The Louvre Gallery’s Abu Dhabi branch showcases White Cement in its detailed geometric layouts, blending art with architectural integrity.

3.3 Industrial and Commercial Applications

Past aesthetics, White cement plays a role in practical settings. It is utilized in industrial floor covering, water-resistant coverings, and chemical-resistant cellular linings. For example, food processing plants count on their hygienefriendly surfaces to satisfy security requirements. In the auto sector, it forms the basis of high-impact immune coverings for display rooms and testing facilities.

3.4 Lasting and Eco-Friendly Projects

With growing focus on sustainability, White cement adds to environment-friendly structure certifications like LEED and BREEAM. Its reflective surface area decreases heat absorption in metropolitan settings, decreasing power usage for air conditioning. Additionally, developments in production approaches have reduced its carbon impact, making it a viable option for environmentally mindful programmers.

4.Verdict: Revolutionizing Modern Building And Construction

White Cement is greater than just a building and construction product– it’s a cutting-edge service that bridges the gap between design and virtuosity. Its unrivaled whiteness, longevity, and flexibility make it vital in a world where design and performance need to exist side-by-side. While its greater expense and level of sensitivity to impurities present existing obstacles, the incentives it offers in regards to aesthetic value and long-term performance are obvious.

For professionals looking to boost their projects, White cement stands for an effective tool. Whether you’re crafting a minimalist home, a vibrant public space, or an industrial marvel, this material has the potential to transform your vision into fact. Accept the white transformation in construction and discover why leading architects and developers worldwide are turning to White cement as their material of choice.

By understanding its secrets– from components to applications– you’re not simply buying a product; you’re purchasing a legacy of development and excellence. Allow White cement to illuminate your next job and redefine what’s possible in the world of design and engineering.

Supplier

Cabr-cement is a supplier under TRUNNANO of white cement with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for white cement, please feel free to contact us and send an inquiry. (sales@cabr-cement.com)

Tags: white cement,white cement price,white portland cement