Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Aerogel Insulation

Silica Aerogel SiO2 Aerogel CAS No.7631-86-9

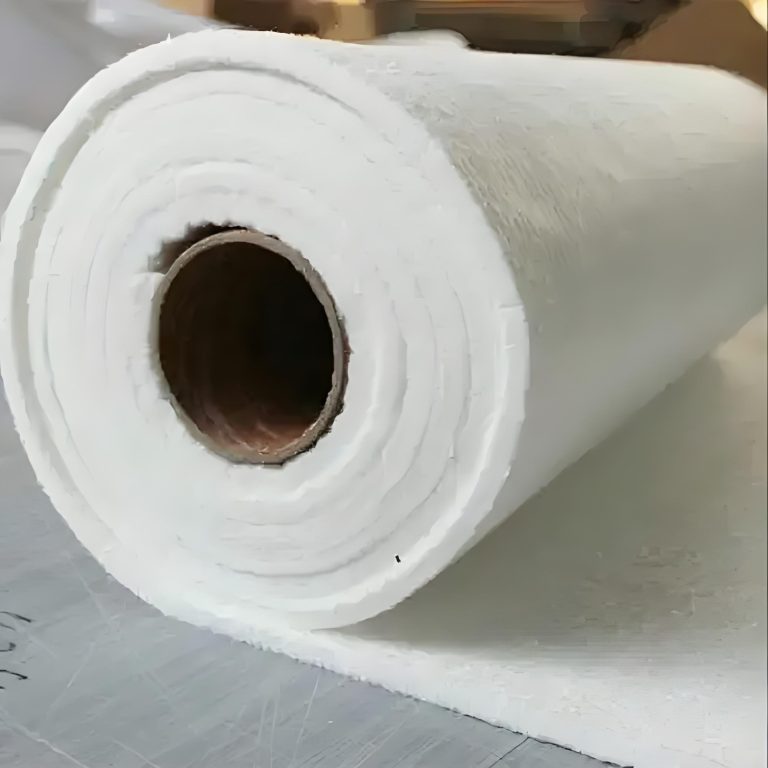

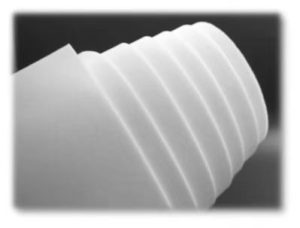

Glass Fiber Reinforced Silica Aerogel Felt

Silica Aerogel Granules

Silica Aerogel Thermal Insulation Coating

Overview of Aerogel Insulation Material

Aerogel is an ultra-light solid material with a nanoporous structure. It is called "solid air" or "frozen smoke" for its excellent thermal insulation performance. It is made by removing the liquid from the gel through special drying technology (such as supercritical drying), retaining the original three-dimensional network structure, with a porosity of up to 80%~99.8%, and a density as low as 3 times that of air.

Thermal Insulation Principle and Features of Aerogel Insulation Material

Nanoporous structure: The pore size of aerogel is extremely small (1~100 nanometers), and it is difficult for air molecules to flow freely in the pores, which effectively inhibits convective heat conduction.

Low solid-state heat conduction: The solid skeleton is composed of nanoparticles or fibers, the heat conduction path is long and tortuous, and the thermal conductivity is extremely low (as low as 0.013~0.025 W/(m·K) at room temperature).

Infrared radiation blocking: Some aerogels (such as silica aerogel) can be doped with sunscreens or reflective materials to reduce infrared heat radiation transmission.

Applications of Aerogel Insulation Material

Building energy saving: used for glass interlayer (such as transparent aerogel windows), wall insulation.

Industrial pipelines and equipment: high-temperature pipeline insulation in the petroleum and chemical industries.

Aerospace: spacecraft insulation layer.

Clothing and outdoor products: ultra-thin warm clothing, hiking boots, etc.

New energy: lithium battery diaphragms, hydrogen storage materials.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Aerogel Insulation Material all over the world. We have a professional technical department and quality supervision department, a well-equipped laboratory with advanced testing equipment and an after-sales customer service centre. Please send us an email or click on the required product to send an enquiry.

If you would like more information about Aerogel Insulation Material, please feel free to contact us at sales1@cabr-concrete.com.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Aerogel Insulation Materials

Q: Why is the thermal insulation performance of aerogel so good?

A: Its nanoporous structure (porosity >90%) can effectively inhibit heat conduction, convection and radiation, and the thermal conductivity is as low as 0.013 W/(m·K).

Q: Is aerogel resistant to high temperatures?

A: Inorganic aerogels (such as silica) are temperature resistant to 650℃+, metal oxide aerogels can reach above 1000℃, and organic aerogels have low temperature resistance (about 200℃).

Q: Is aerogel easy to break?

A: Pure aerogels are relatively brittle, but they can greatly increase the strength through composite fibers (such as glass fibers) or flexible polymers to make practical forms such as flexible felts and plates.

Q: Is aerogel waterproof?

A: Unmodified aerogels may absorb hygroscopicly, but after hydrophobic treatment (such as silane modification) are superhydrophobic (contact angle >150°), suitable for humid environments.

Q: Why are aerogels expensive?

A: The main reason is that the production process is complex (such as supercritical drying), but large-scale production and technological improvements (such as atmospheric pressure drying) are gradually reducing costs.