Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Concrete Admixture Equipment

Liquid Concrete Admixture Compounding Equipment

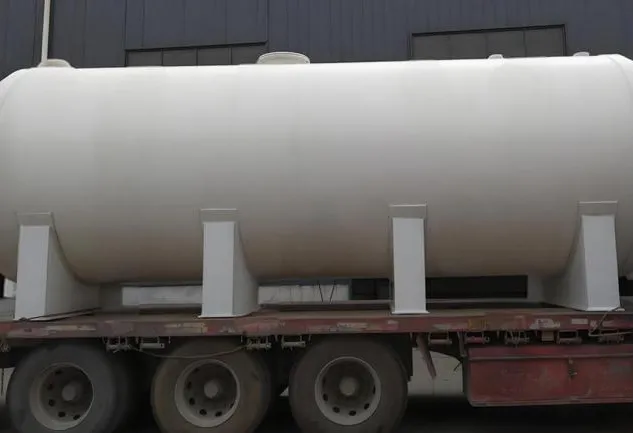

Concrete Liquid Admixture Anti-corrosion Transport Tank

Anti-Corrosion Storage Tanks for Liquid Concrete Admixtures Equipments

Concrete Accelerator Production Equipment Concrete Admixtures Producing Machine

Cement Grinding Aid Production Equipment Concrete Admixture Producing Machine

Naphthalene Sulfonate Superplasticizer Machine Producing Equipment Machine

Polycarboxylate Superplasticizer Production Equipment Water Reducer Producing Machine

Introduction to Concrete Admixture Equipment

Concrete admixture equipment is a complete set of machinery specialized in the production, storage, transportation, and compounding of various concrete admixtures. This includes production lines and supporting systems for a variety of products, including polycarboxylate water reducers, naphthalenesulfonate water reducers, cement grinding aids, and accelerators. This equipment features high precision, corrosion resistance, and a high degree of automation. It is widely used in building materials, chemical processing, ready-mixed concrete, precast components, and engineering construction. It is key to achieving efficient, stable, and environmentally friendly admixture production.

Features and Advantages of Concrete Admixture Equipment

- High-Precision Control: Utilizing a PLC/DCS automation system, key parameters such as mix ratio, temperature, and pH are precisely controlled, with an error of ≤±0.5%.

- High Corrosion Resistance: Made of stainless steel (304/316L), polypropylene (PP), or lined with an anti-corrosion coating, it is compatible with a variety of chemical media, including acids, alkalis, and salts.

- Flexible Adaptability: Supports both batch and continuous production, and can be customized to meet varying production capacities (e.g., 5-30 tons/batch) and product forms (liquid/powder).

- Safe and Reliable: Equipped with explosion-proof, leak alarm, over-temperature and over-pressure interlocks, and meeting chemical production standards.

- Energy-Saving and Environmentally Friendly: Closed production reduces volatilization, cleaning systems prevent cross-contamination, and support waste liquid recycling.

Applications of Concrete Admixture Equipment

- Production of polycarboxylic acid-based and naphthalene-based water reducers;

- Preparation and processing of cement grinding aids and accelerators;

- Corrosion-resistant storage and safe transportation of liquid admixtures;

- Admixture compounding and supply for commercial concrete mixing plants;

- Customized production of specialty engineering materials (such as accelerators for tunnels and mines.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality concrete admixture. We have a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Concrete Admixture Equipments, please feel free and contact us: sales@cabr-concrete.com

FAQs About Concrete Admixture Equipment

Does the equipment support automated operation?

Yes, most equipment is equipped with a PLC or DCS system, enabling fully automated batching, reaction, mixing, and cleaning, and remote monitoring.

What are the main equipment materials? How should they be selected?

Commonly used materials include stainless steel (304/316L), polypropylene (PP), and fiberglass reinforced plastic (FRP). The selection should be based on the corrosiveness of the media, temperature, and process requirements.

Can the equipment produce both liquid and powder products?

Yes, by configuring a reactor, spray dryer, and packaging system, dual-line production of liquid and powder products can be achieved.

How is safety ensured during production?

The equipment features explosion-proof design, leak detection, emergency stop, and automatic alarm functions. Operators are required to wear protective equipment.

Are customized solutions available?

We support customized equipment design and turnkey solutions based on customer production capacity, formulation, site requirements, and other requirements.